Why modular?

Modular infrastructure: tomorrow’s solution, today

Surgical backlogs. Poor indoor air quality and circulation. Housing shortages. At its core, each of these issues is an infrastructure challenge—a challenge that our modular construction process is designed to meet and surpass, affordably and effectively.

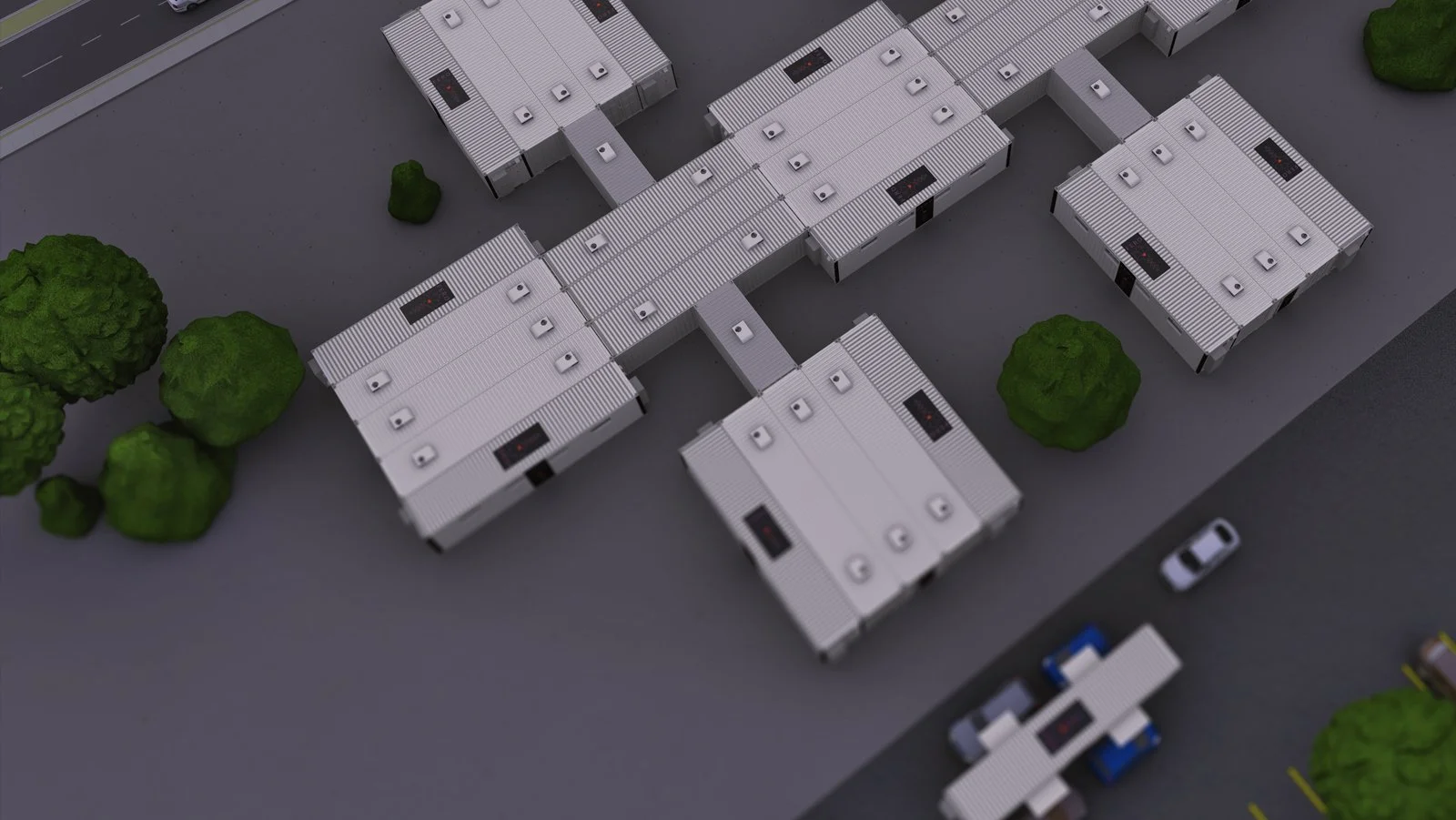

All of our products, whether for shelter, medicine, emergency utilities or long-term power generation, are designed to work as both individual units and as complementary pieces of much larger installations. Our engineering ensures that each unit can be easily transported and withstand extreme climates. Fully customizable and rapidly scalable, the building blocks of your next infrastructure project are ready for you at Fero.

Innovating is our business

Our products can be used for a variety of applications, from surgery, intensive care units and patient rooms to temporary shelter and permanent housing. Decentralized, HEPA-filtered HVAC systems promote exceptional air quality and full control over heating and cooling, while robust engineering ensures comfort and care amid extreme temperatures and weather. To ensure a fast, turnkey installation, we can install all of the necessary equipment, then ship each unit to you by road, rail or sea.

See how our innovative modular construction can be applied in your sector:

Healthcare | Mining | Military | Housing | Indigenous communities

See how it all comes together

The benefits of modular construction

Shorter build time: Modular construction is a disruptive method for creating state-of-the-art infrastructure more quickly. Our proprietary prefabrication process at our North American factory takes on average 20 to 30 percent less time to complete than traditional construction. And because flexibility is at the core of our approach, each Fero unit can be installed quickly onsite, allowing you to easily scale up and down on a unit-by-unit or room-by-room basis.

Quicker return on investment: Tighter turnaround times mean fewer cost surprises. Faster deployment means you can start reaping the benefits of your investment sooner.

More sustainable: Since most materials are delivered to our factory, modular construction means fewer trucks at your project site. Fewer vehicles mean less air and noise pollution. Our onsite manufacturing reduces waste and allows us to use more lean manufacturing methods and adhere to environmental principles. Plus, prefab construction waste—from packaging to steel—is easier to recycle, since it hasn’t been exposed to the elements.

Year-round construction: Our facility allows construction crews to work from the inside, through the worst weather conditions, all year round.

Ready for winter: Typical construction methods can span several seasons. Indoor construction and quick installation make our modular systems a great choice for projects in harsh climates and hard-to-reach locations.

Limited site disruption: The same factors that make modular ideal for difficult environments are also assets when you need to keep business or site activity flowing: limited onsite building at mines, hospitals, schools and more.

Focus on quality control: Our in-house engineering and production ensure projects are built to the highest standards of quality.

Want to know more?

Contact us today to find out how Fero’s modular solutions can be the building blocks of your next infrastructure project.